Welding machine Manufacturer supplier

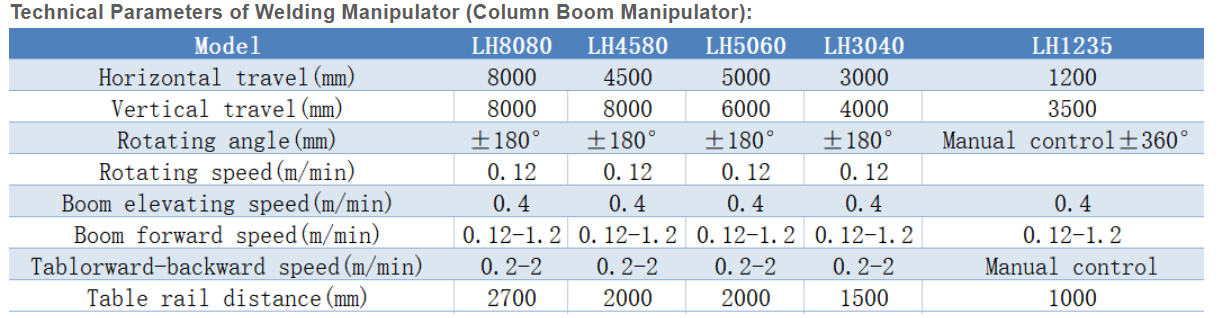

This Welding manipulator, also called column boom manipulator, is mainly installed with the TIG and MIG welding machine. And we can provide you with three types of welding manipulators for our clients: radial-position, fixed.

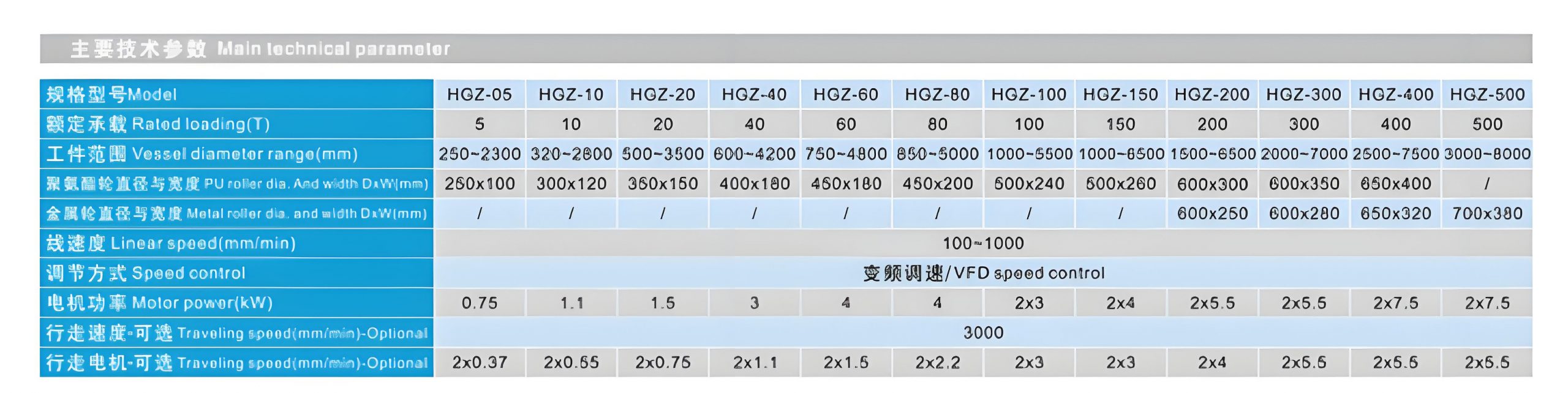

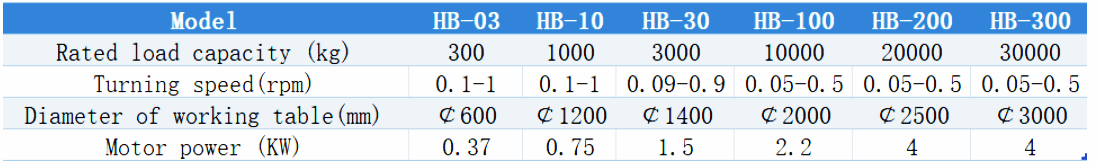

This Welding positioner, also called welding positioning equipment, is mainly used for some special structures, construction machines, small round workpieces, and more. And it mainly consists of a working table, turning device, overturning device

This welding turntable is mainly used for welding and assembling workpieces, and it is widely used in presser vessel production industry, petrol industry, chemistry, power stations, transportation, shipbuilding industry, steel field, and so on.

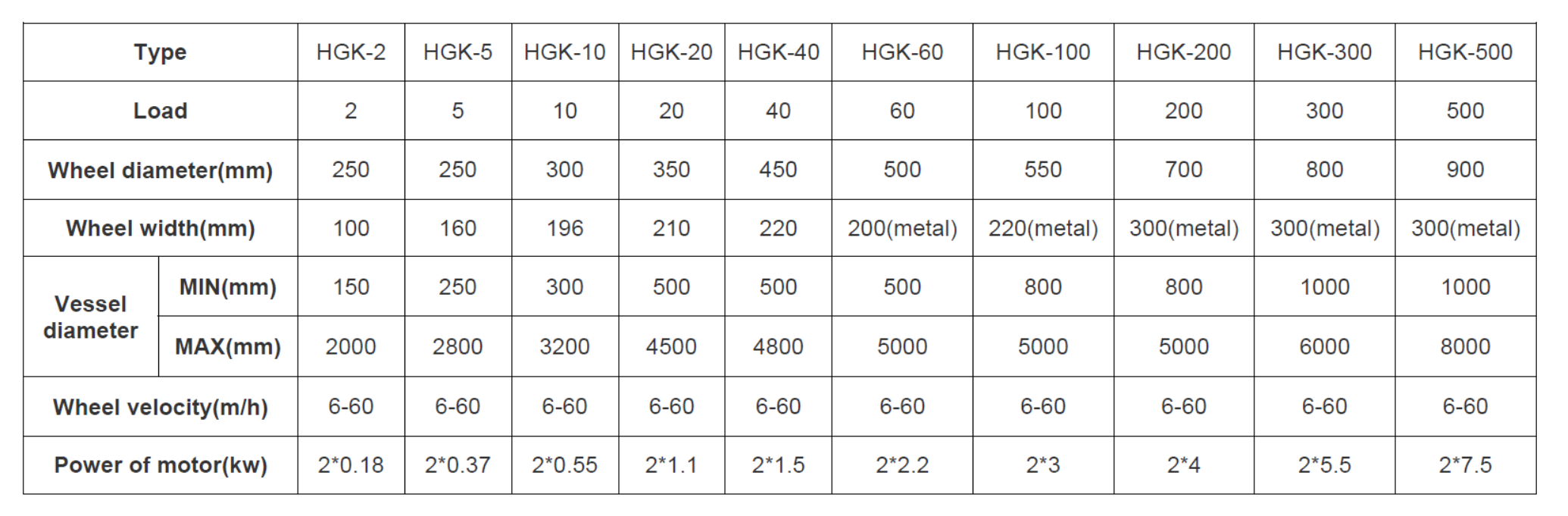

Our HGK-type adjustable welding rotator is designed for handling and automatic welding circular metal containers, and it mainly used in oil industry, press vessel field, wind tower production line, pipe line production field.

Our standard welding rotator is mainly used for handling and automatic welding circular metal containers, and can be widely applied to oil industry, press vessel field, wind power production line, pipe line production sector

To better satisfy our clients’ demands on various welding rotator, our company can provide various special welding rotators for your choice, such as PU wheel rotator, hydraulic lift rotator, fit-up rotator, and more.

Hydraulic lifting equipment, storage tank installation equipment. Mainly used for all kinds of flip large storage tank, gas holder, power plant desulfurization tower steel structure lifting installation.The translation of large weights is also generally

CO2 automatic welding trolley is widely used in ships, bridges, locomotives, steel structure, oil and chemical industry, suitable for various welding structure of welding, such as: stiffened plate, floor, cross site welding, box girder welding, and so on.

Our standard welding rotator is mainly used for handling and automatic welding circular metal containers, and can be widely applied to oil industry, press vessel field, wind power production line, pipe line production sector

The H beam assembly machine is applicable to different kinds of H beam steel such as symmetry, dissymmetry, eccentricity and variable cross-section assembly and spot-weld.

The gantry welding machine is widely used welding equipment. This machinery usually uses submerged arc welding. And when the machine is in welding work, it is appears that the work piece.

This H beam flange straightening machine is widely used in welding works for the purpose of correction of the steel flange and straighten the flange plates. In the welding process.

Mainstream products

Embrace the future of welding with our state-of-the-art solutions.

From advanced automation to user-friendly controls, our innovative products empower you to lead in today’s competitive market!

Wuxi ABK stands at the forefront of self-aligning rotor innovation, leveraging 20+ years of specialized expertise to deliver precision-engineered solutions for global industries. Our rotors, renowned for unmatched durability and adaptability, excel in high-demand applications—from manufacturing automation to energy systems. By integrating a seasoned technical team with cutting-edge R&D and ISO-certified quality protocols, we not only ensure seamless performance but also empower clients with rapid, customized support, reducing downtime and driving sustainable growth across every partnership.

WUXI ABK redefines precision in welding automation as a global innovator of advanced auxiliary systems. Our engineered rotators—featuring PU wheel, hydraulic lift, and intelligent fit-up technologies—are purpose-built to optimize fabrication of pipelines, wind towers, and pressure vessels. Beyond hardware excellence, we fuse adaptive design with ISO-certified manufacturing, translating complex industry challenges into tailored solutions that accelerate production timelines while ensuring millimeter-perfect alignment, durability, and lifecycle ROI.

WUXI ABK Welding Positioner handles special structures, machinery, and small round workpieces with precision. Features 6-slot tables, stepless speed control, and Q235-A steel stands for durability. Integrated frequency conversion and electricity-conducting shafts ensure stable welding. Customizable designs adapt to client needs. As a factory-direct manufacturer, WUXI ABK delivers cost-efficient, high-precision solutions for diverse industrial applications.

WUXI ABK Welding Turntable automates welding in pressure vessels, shipbuilding, and chemical sectors. Features a 6 T-slot worktable with stiffeners, worm gear stability, and stepless speed control for precision. Customizable designs ensure low maintenance and high rigidity. As a factory-direct manufacturer, WUXI ABK delivers cost-efficient, durable solutions for circular welding and complex industrial applications.

WUXI ABK Welding Manipulator delivers precise TIG/MIG support for vessels, pipelines, and cylindrical workpieces. Featuring radial/fixed/rotary configurations, it adapts to diverse diameters with optional tracing/monitoring. Seamlessly integrates with turning rolls and automated systems. As a factory-direct manufacturer, WUXI ABK ensures cost-efficient, stable welding solutions for pressure vessels, construction, and chemical industries.

Why choose us

Proven Expertise

Over 20 years of industry experience with a track

record of successful international projects.

High-Quality Products

Our equipment is built for durability, precision, and

efficiency, adhering to the highest standards.

Wide Application Range

Our products serve a variety of industries, offering

tailored solutions to meet specific needs.

Competitive Pricing

We provide cost-effective, high-performance

equipment without compromising on quality.

Custom Solutions

We offer customizable equipment to meet your

unique project requirements.

Our Professionals Are Always Ready to Help You, Contact Us Today!

Customer evaluation

FAQ

FAQ 1: What is the maximum load capacity of your Welding Rotator? Can I customize equipment for larger loads?

A: Our standard welded roller frame load capacity varies from 1 ton to 100 tons, depending on the model. If you have special needs, we can provide customized solutions based on the size and weight of your workpiece to ensure that the equipment fully meets your production requirements.

FAQ 2: Is it possible to adjust the rotation speed of the Welding Positioner? How accurate is it?

A: Yes, our welding positioner is equipped with stepless speed regulation, and the rotation speed can be flexibly adjusted according to your welding process needs. At the same time, the equipment adopts high-precision servo motor to ensure that the rotation accuracy reaches ±0.1°, which is suitable for high-precision welding tasks.

FAQ 3: Does your Welding Manipulator support automated welding? Can it be integrated with existing welding robots?

A: Absolutely! Our welding manipulators support fully automated operation and are equipped with standard interfaces, which can be easily integrated with mainstream welding robots (such as ABB, KUKA, FANUC, etc.) to achieve efficient and accurate automated welding production lines.

FAQ 4: What is the quality and durability of the equipment? Are there any certifications?

Our equipment is made of high-strength steel and undergoes rigorous quality testing to ensure durability and reliability. All products are ISO 9001 quality system certified and CE certified, in line with international standards, you can use it with confidence.

FAQ 5: What after-sales service do you provide if there is a problem with the equipment?

A: We provide comprehensive after-sales service, including:

1)24 months warranty;

2)Free remote technical support;

3)Rapid response on-site repair service;

4)Lifetime supply of spare parts.

Our goal is to ensure that your equipment is always running at its best.

FAQ 6: Does your equipment support customization? How long does the lead time take?

A: Yes, we offer fully customized solutions to design the equipment according to your workpiece size, welding process, and production needs. Lead times are 4-6 weeks for standard equipment and 6-8 weeks for customized equipment depending on complexity. We specify the delivery time in the contract and ensure that it is delivered on time.

1). “Consult an expert for a customized welding solution today!”

Our team is on hand to provide you with expert advice and help you choose the most suitable equipment. Click the button below to start your journey to efficient welding!

2). “Limited Time Offer! Order now and enjoy exclusive discounts and technical support! ”

Don’t miss this opportunity! Contact us today for exclusive discounts and professional technical support to make your production more efficient and hassle-free!

3). “Check out the success stories and see how we’re creating value for our customers!”

Explore our customer stories and see how we’re helping businesses like yours become more productive. Click here to learn more and start your path to success!